In the realm of life sciences laboratories, samples hold utmost importance. Thus, preserving, storing, and retrieving them with integrity is imperative. 2D barcodes play a pivotal role by storing extensive data both vertically and horizontally, allowing for the storage of a large amount of information. A single 2D code can accommodate up to 3,116 numeric characters or 2,335 alphanumeric characters.

Notably, AltemisLab’s 2D barcodes feature built-in error correction, effectively eliminating misreads. All of our 2D barcodes are meticulously laser-etched onto the black polypropylene base of our tubes.

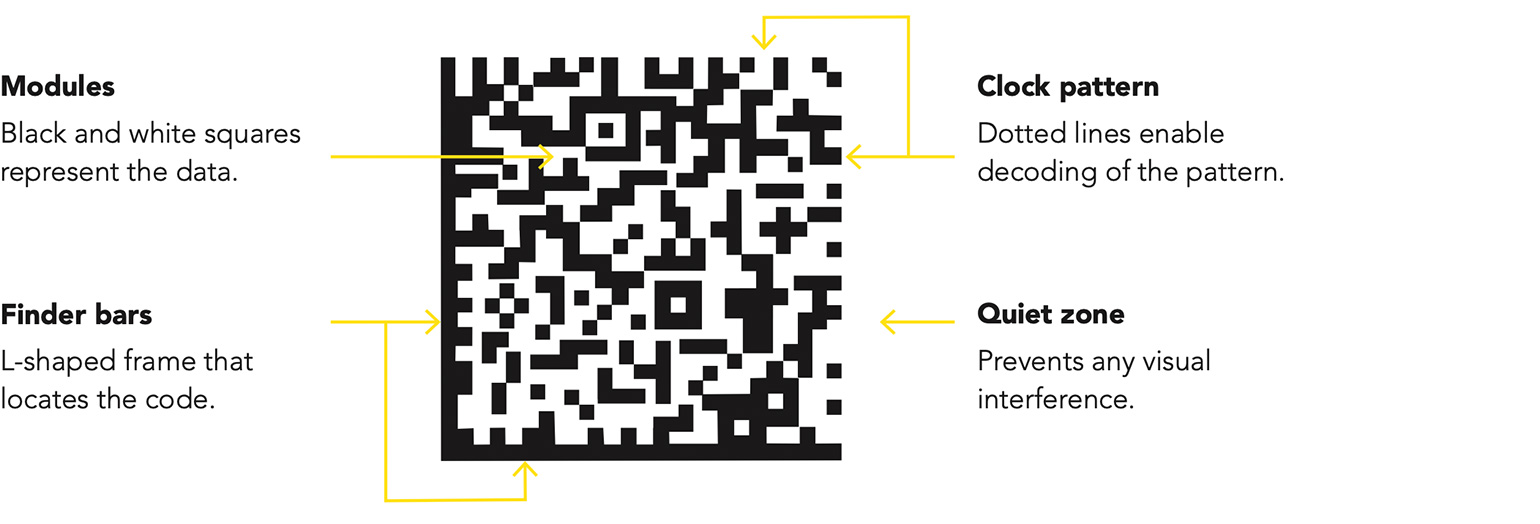

Anatomy of a 2D DataMatrix barcode

Code recovery built into ECC200

Reed-Solomon error correction reconstructs and verifies data for improved accuracy. DataMatrix codes can still be decoded if damaged by 30%.

Benefits of 2D DataMatrix barcodes

– Never misreads or reports a wrong number

– Readable at contrast levels as low as 20%

– Significantly smaller compared to 1D barcodes

The manufacturing process of the AlteTube incorporates dual injection molding using virgin polypropylene for the tube and black polypropylene for the base, which is subsequently laser-etched with a unique 2D barcode. These components are melded during the plastic’s malleable phase, resulting in a single-piece tube.

Laser etching stands out as one of the most secure methods for applying a 2D barcode to a tube. Its chemical and mechanical resistance provides assurance when handling and storing samples, ensuring peace of mind.

Every 2D barcode undergoes a quality check during the manufacturing process. Each tube is scanned using a 2D barcode reader to verify its decoding. If a tube fails to decode, it is promptly rejected from the manufacturing process, and the associated barcode number is not reused.

But what is the best way to read and work with 2D barcoded tubes?

Having a secure and efficient sample tracking solution is vital. ScanID from Flow Robotics offers both 1D and 2D scanning on one device and can scan an entire rack of sample tubes in one go.

After scanning, the racks are placed in the liquid handler flowbot® ONE, which now holds all the sample IDs, for further processing. Automation will not only ensure a higher throughput and relieve lab technicians but also help eliminate misplacement errors.

The pre-analytical phase remains the most error-prone part of laboratory testing due to its complexity and heavy manual workload. In fact, it is estimated that pre-analytical errors account for up to 70% of all mistakes made in laboratory diagnostics. Manual tasks such as pipetting and tracking play a big part in this.

Product manager Rob Pickles says “the creation of the ScanID required verification of many variables that were critical to its robust and reliable operation. AltemisLab managed to remove at least one of these variables via its high-quality data matrix print with high contrast. AlteTubes remain the reference tube for the ScanID.”

On an even more serious note, studies show that between 24% and 30% of laboratory errors influence patient care, and that patient harm occurs in between 3% and 12% of cases. This is one of the real-life laboratories struggles that Flow Robotics wishes to amend.

“We believe that our sample tubes are in good hands with ScanID which also acts as an error-control by warning us if two barcodes are identical,” says Thomas Sundelin, Molecular Biologist at Herlev Hospital.