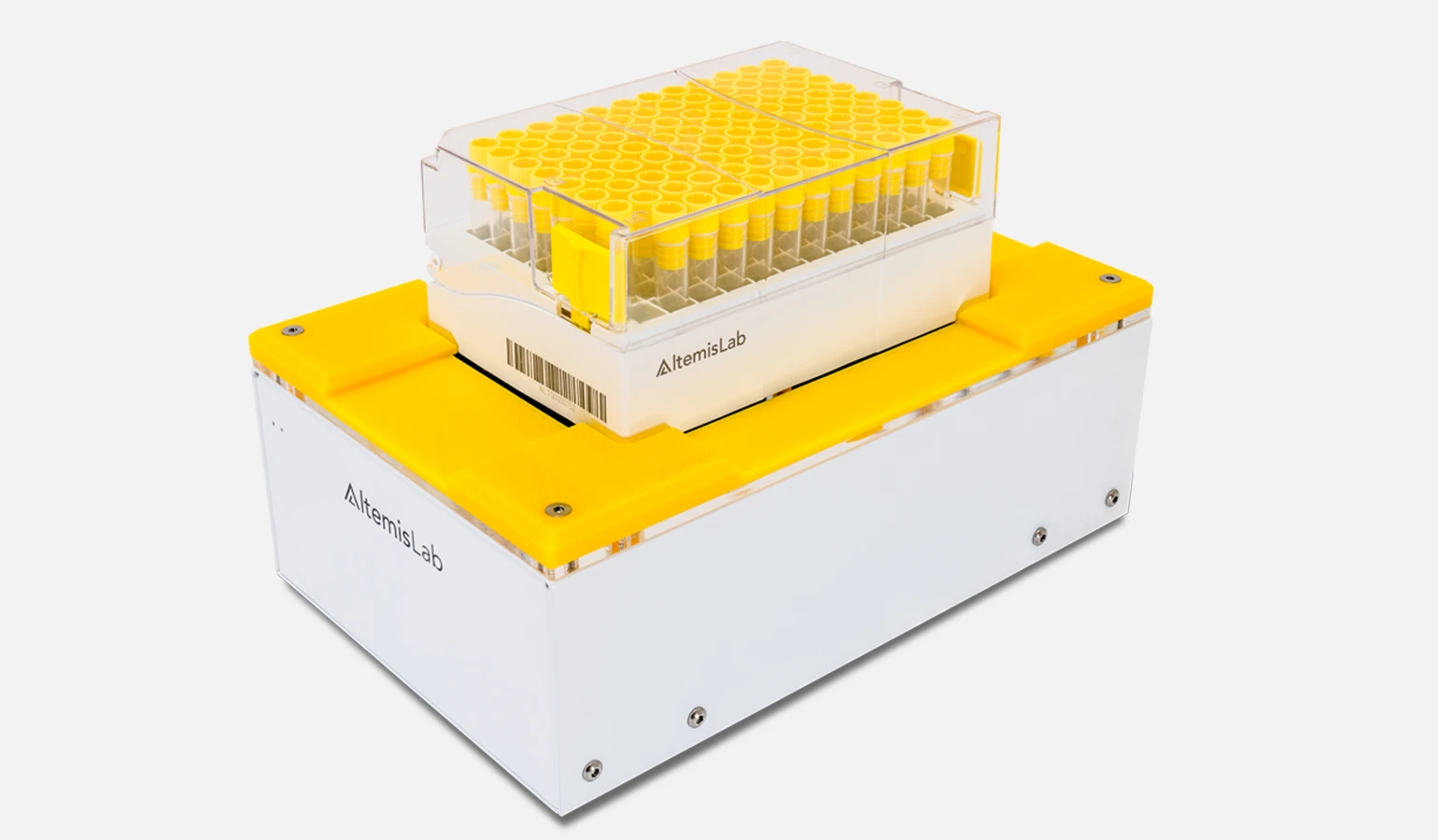

A frequent challenge researchers face when reading 2D barcodes, arises when racks and tubes need to be read straight from cold storage. Since 2D barcode readers are optical devices, they are reliant on clear visibility of the barcodes on the tube bottoms and any layers of ice that have built up may pose a problem. Below we share our top tricks and tips to ensure seamless barcode reading.

Remove any frost

Frost covering the barcodes. There is no barcode reader on the market that can decode the 2D barcode without being able to visualise it.

Use a 100% Ethanol bath or a better term, the de-frosting method

Be careful how you all use the term ‘ethanol bath’. The term ethanol bath may mean to some people fully submerge the rack in a bucket. We would recommend just calling it the ‘de-frosting method’ and then explain that ethanol will only come in contact the bottom of the tubes and will not cause the samples to thaw.

Please note – working with ethanol baths will not damage our CryoCover™ only cleaning with alcohol wipes/ethanol or abrasives will damage this.

Do not leave the rack on the reader too long

As soon as the actual read is complete the rack needs to be taken off the reader (when our read light goes out).

Configure – Settings

Options – Experiment with turning the auto-repeat feature on to a maximum (repeat 5 repeat reads).

Time Out Settings – Experiment turning on the number of seconds before abort (maximum 120 seconds).